Critical temperature

Temperature rises have a significant impact on the mechanical properties of steel. At 400°C, the yield strength of the steel is reduced to 60% of its original value. It has been proven that a steel structure subjected to heat will lose its load-bearing capacity after a certain time and collapse.

The temperature at which this occurs is called the critical temperature.

This critical temperature will differ depending on the weight of the initial load and, in particular, on the degree of permissible stress and the nature of that stress.

For the purpose of simplification, the following minimum critical temperature values can be used on the basis of Eurocode 1993-1-2 :

- 500 °C for compressed elements or elements subjected to axial bending and compression.

- 540 °C for isostatic beams and tension members.

- 570 °C for hyperstatic beams.

Section factor S/V

The section factor expresses the ratio between the surface area exposed to the heat flux S [m2] and the volume of an element per unit length V [m3]. Its value has a significant effect on the fire behaviour of a given structural element.

An element with a low S/V quotient [m-1] will heat up much more slowly than an element with a high section factor. It will therefore have a higher fire resistance

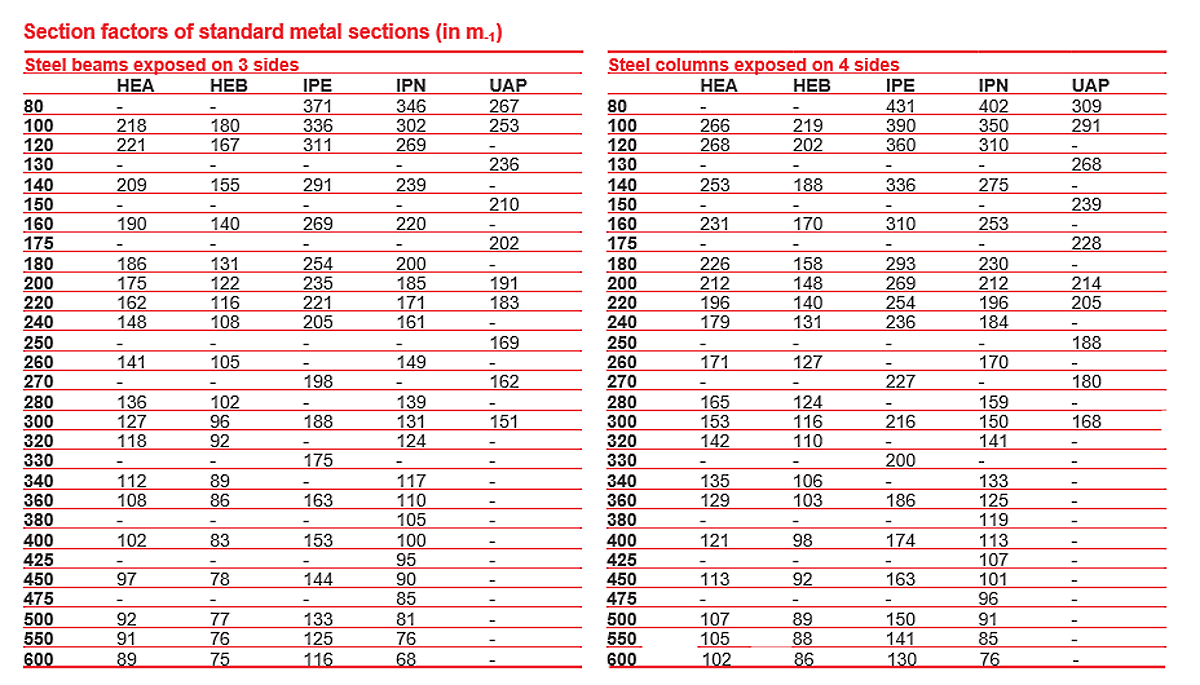

The following table gives the mass factors of common steel sections for 3-sided exposed beams and 4-sided exposed columns. For other types, please contact Projiso’s technical department.