Acoustic correction and attenuation of concrete structures: Fibrexpan®

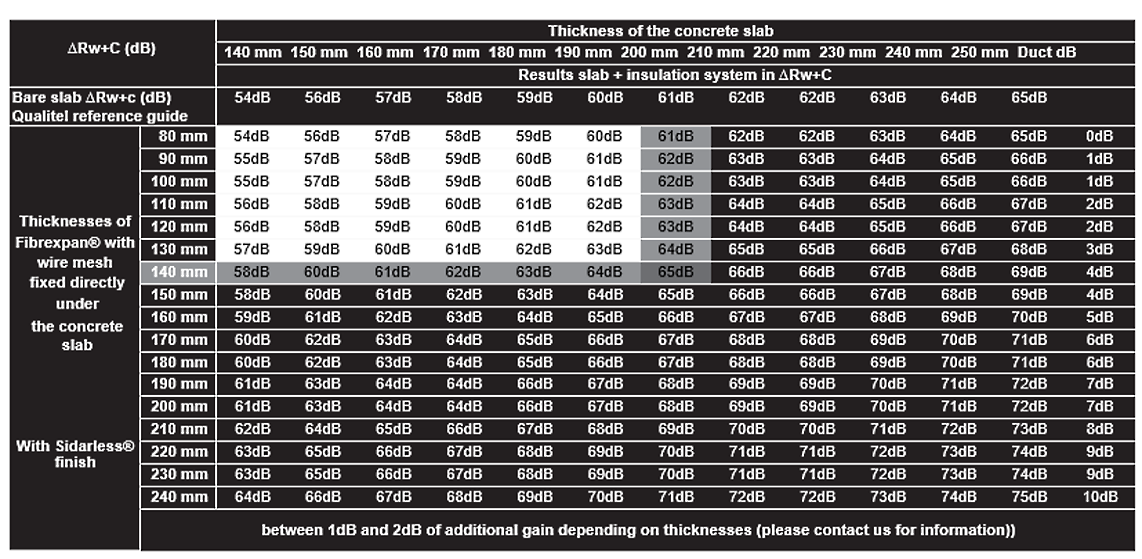

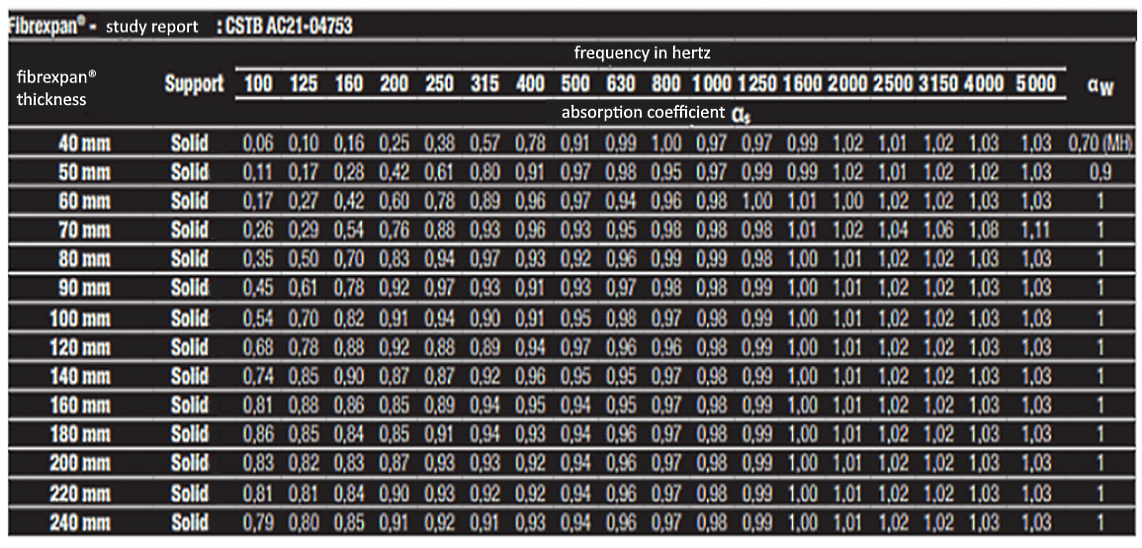

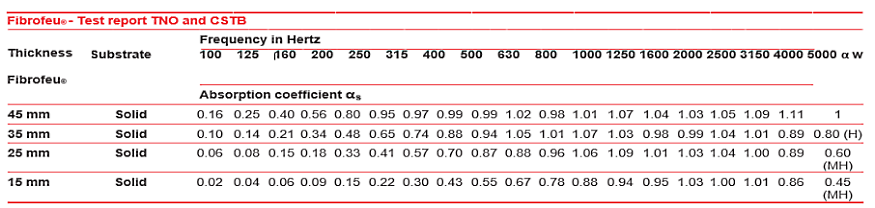

Projiso proposes an innovative solution, based on the spray-on application of Fibrexpan® to improve sound insulation between superimposed spaces. The principle consists in spraying the Fibrexpan® coating in one or more layers to achieve the desired thickness.

Fibrexpan® is a dry, non-toxic, CE-marked material composed of slag wool, hydraulic and semi-synthetic binders and various additives It is supplied in flake format(insérer un lien vers le produit)

Fibrexpan® is a spray-on product; the sprayed thickness will be defined according to the desired acoustic attenuation. Flocking consists in applying Fibrexpan® fibres under pressure using special machines.

The product is carded in a spraying machine that generally comprises a feed hopper, a carding device, a blowing device (fan, turbine or blower), a hose for conveying the mixture to be sprayed to a spray gun using compressed air. Water-fed nozzles are placed around the hose outlet to wet the product before it is sprayed onto the substrate.

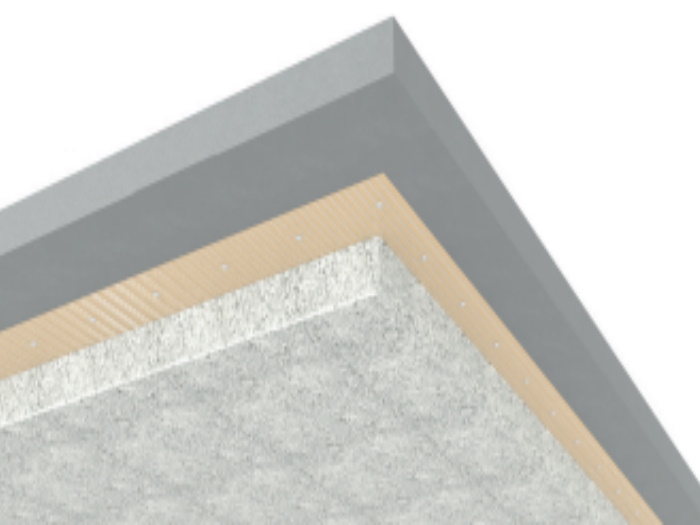

The assembly principle consists in fixing an expanded metal sheet to the concrete slab.

Fibrexpan® is then sprayed onto this sheet in one or more layers until the desired thickness is reached.

The thickness of the Fibrexpan® coating to be sprayed onto the concrete slab will vary depending on the desired acoustic attenuation value