The use of Firespray® in the fire protection of steel floor trays

Firespray® consists of slag wool, with hydraulic and inorganic binders. It is supplied in the form of light flakes.

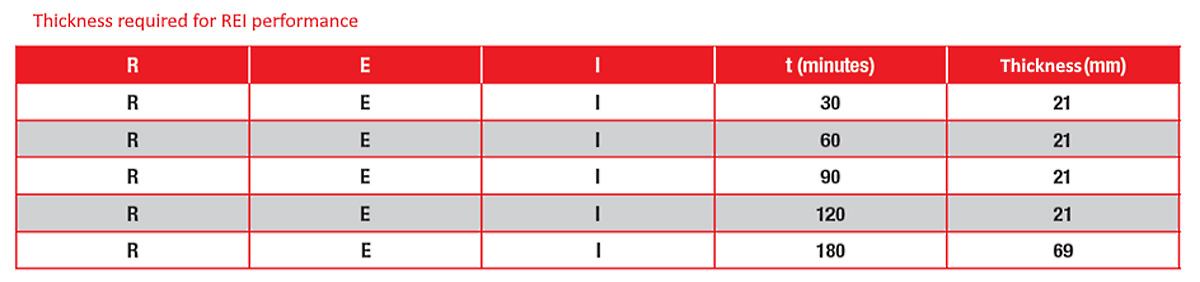

The thickness of the fire protection coating varies between 21 and 69 mm.

Beam height must be at least 120 mm.

The assembly involves placing M48 spacers directly on the bottom flanges of the structural beams at right angles with a maximum spacing of 600 mm. Screw-fix an expanded metal sheet, type Nerfloc, and apply Firespray® to the desired fire protection rating.