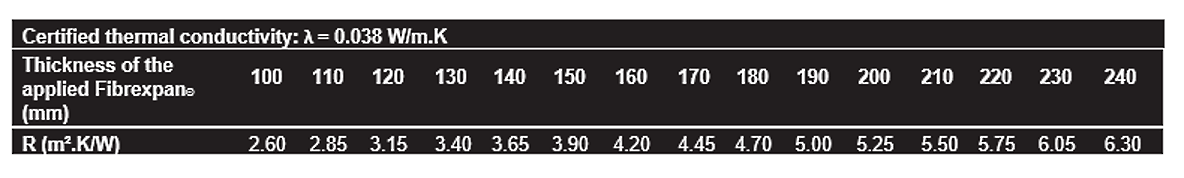

Fibrexpan® is ACERMI-certified with respect to conductivity and thermal resistance values

ACERMI is the result of a dual commitment:

• That of the manufacturer who undertakes to put in place a quality system and the necessary means to control the quality of its products and the maintenance of this quality over time.

• That of the certifier, an independent, competent and recognised body, whose role is to guarantee the truthfulness of the announced characteristics and to re-evaluate them periodically.

ACERMI certification, which guarantees the thermal properties of the product when it leaves the factory, is supplemented by a Unified Technical Document (DTU 27.1).

This specific DTU 27.1 document is used to validate:

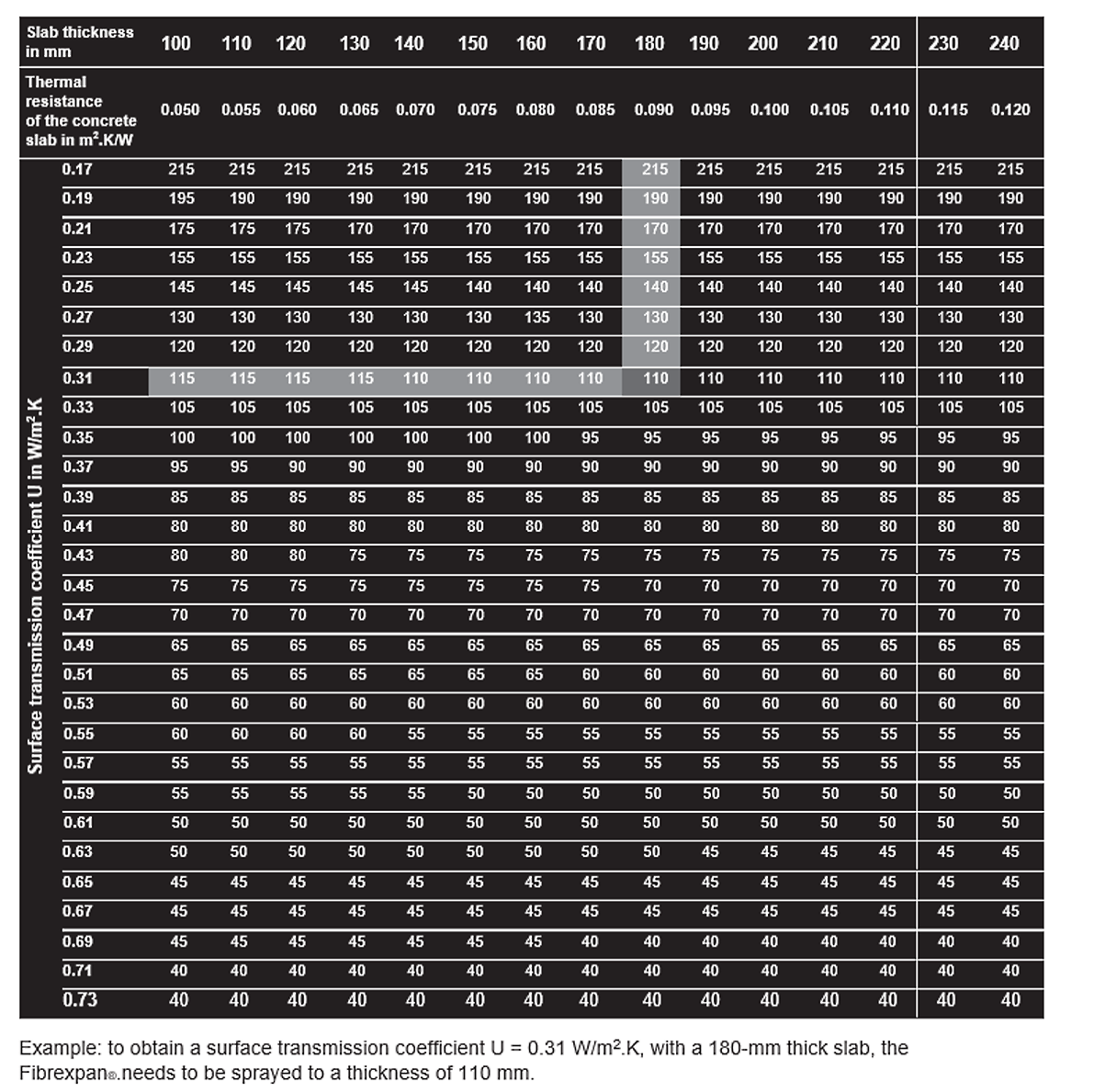

• Application of Fibrexpan® up to a thickness of 240 mm on a concrete support, with no intermediate reinforcement

Conditions of implementation regarding Fibrexpan®

Precautions to be taken in order to achieve high-quality spraying.

DTU 27.1 also defines a self-checking method, which is essential to justify that the performance guaranteed by ACERMI certification, when leaving the factory, is reproduced on

the worksite. The results of the self-checks are reported in the worksheet.

The objectives of the worksite datasheet are to:

• Mark out the quantity of insulation sprayed,

• Ensure traceability from the finished product in bulk, leaving the factory, to the finished product, applied on site (part 2 of the sheet),

• Guarantee the thermal performance according to an installed density and thickness per machine and per thickness.

The form is produced in triplicate:

• One copy is kept by the spray application technician,

• One copy is kept by the principal,

• Once copy is kept by the contracting authority.

These supporting documents must be kept for at least 10 years and according to the regulations in force.

A form must be filled in for each machine and each spraying thickness (i.e. for each setting).