The application technique of Firespray®

The assembly involves placing M48 spacers directly on the beams at right angles with a maximum spacing of 600 mm. Screw-fix an expanded metal sheet and apply Firespray

® to the desired fire protection rating.

Firespray

® is spray-applied under pressure, using a special machine.

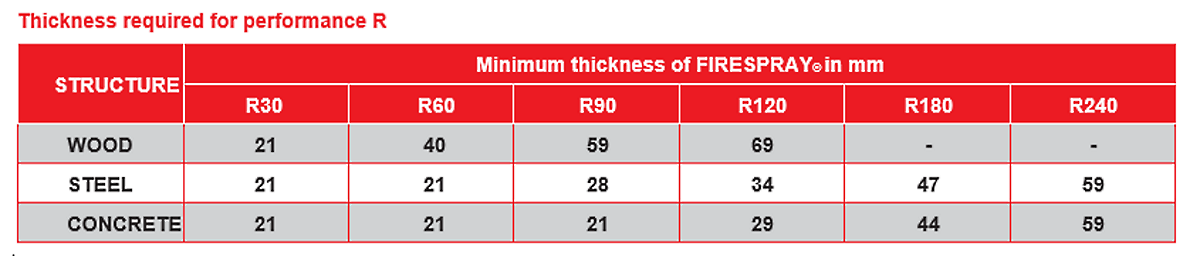

The thickness of the sprayed layer will be defined according to the desired fire resistance rating.

The spraying machine comprises a feed hopper, a carding device, a blowing device (fan, turbine or blower), a hose for feeding the Firespray

® into the spray gun, and water.

Water-fed nozzles are placed around the hose outlet to wet the product before it is sprayed onto the substrate.

Firespray

® does not require prior application of a bonding agent.

The coating will be finished with Projiso

Fixo Dur® or

Sidairless®.

Projiso Fixo Dur

®, which acts by impregnation, is a complex mixture of silicates and acrylic copolymers in the water phase. Or Sidairless

®, a fine, ready-to-use coating that can be tinted for a decorative finish.